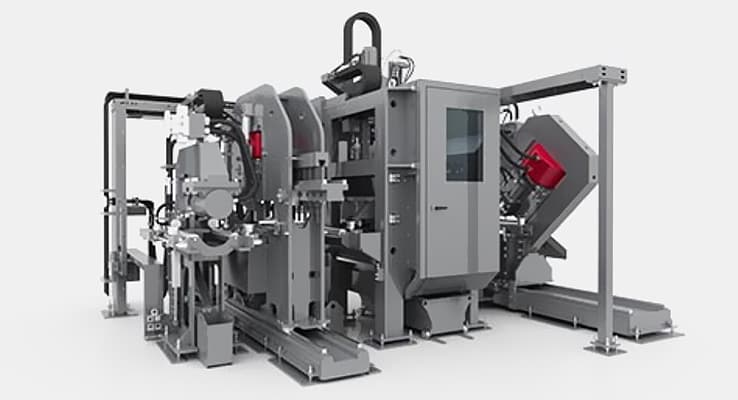

Equipment

Gulf States Saw & Machine Co., Inc. is the largest saw-blade shop within the southeast. We have over 50,000 products in our supply catalog that we can offer to our customers. We value our clients as much as large sales. It is our priority to provide 24/7 customer service.